On Demand Vapor Control

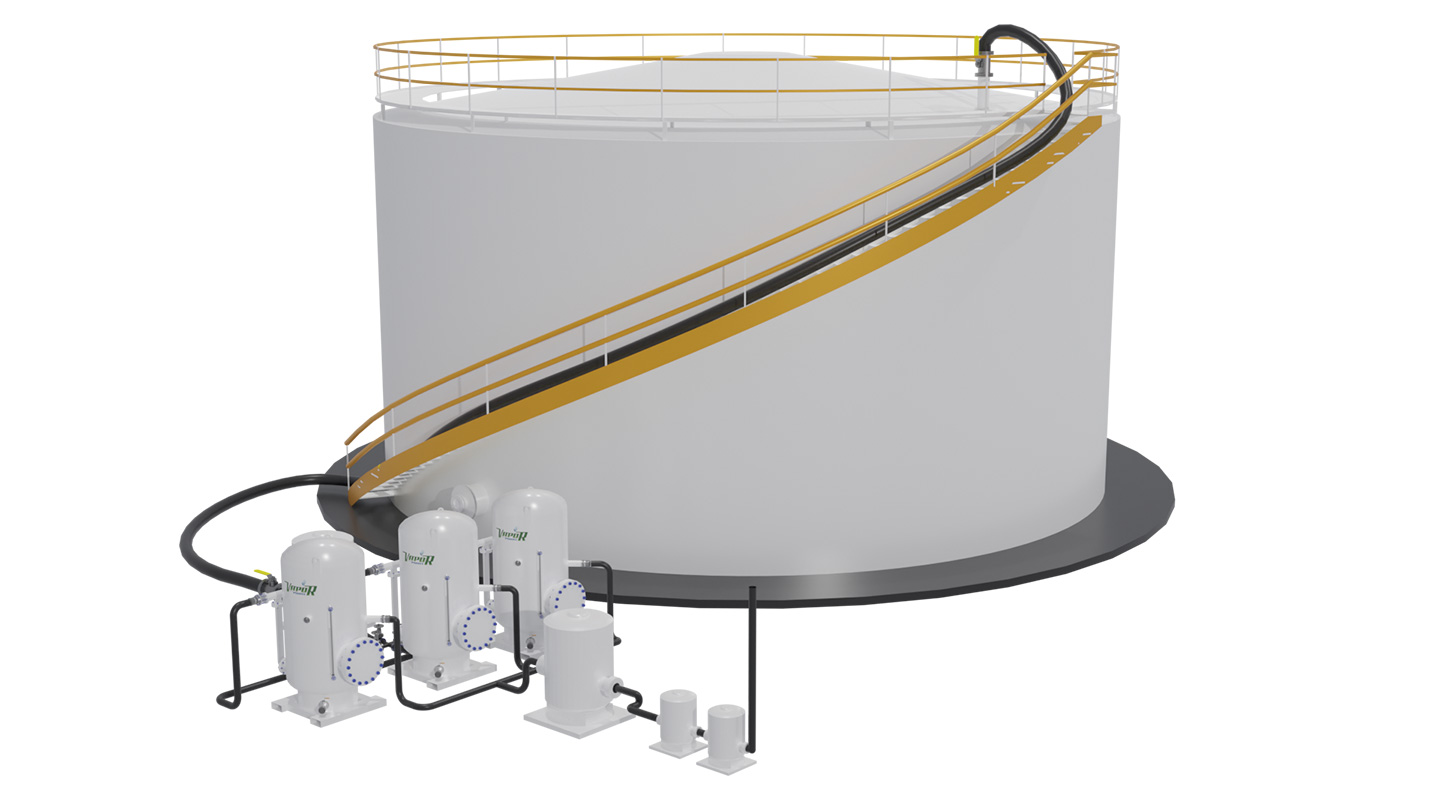

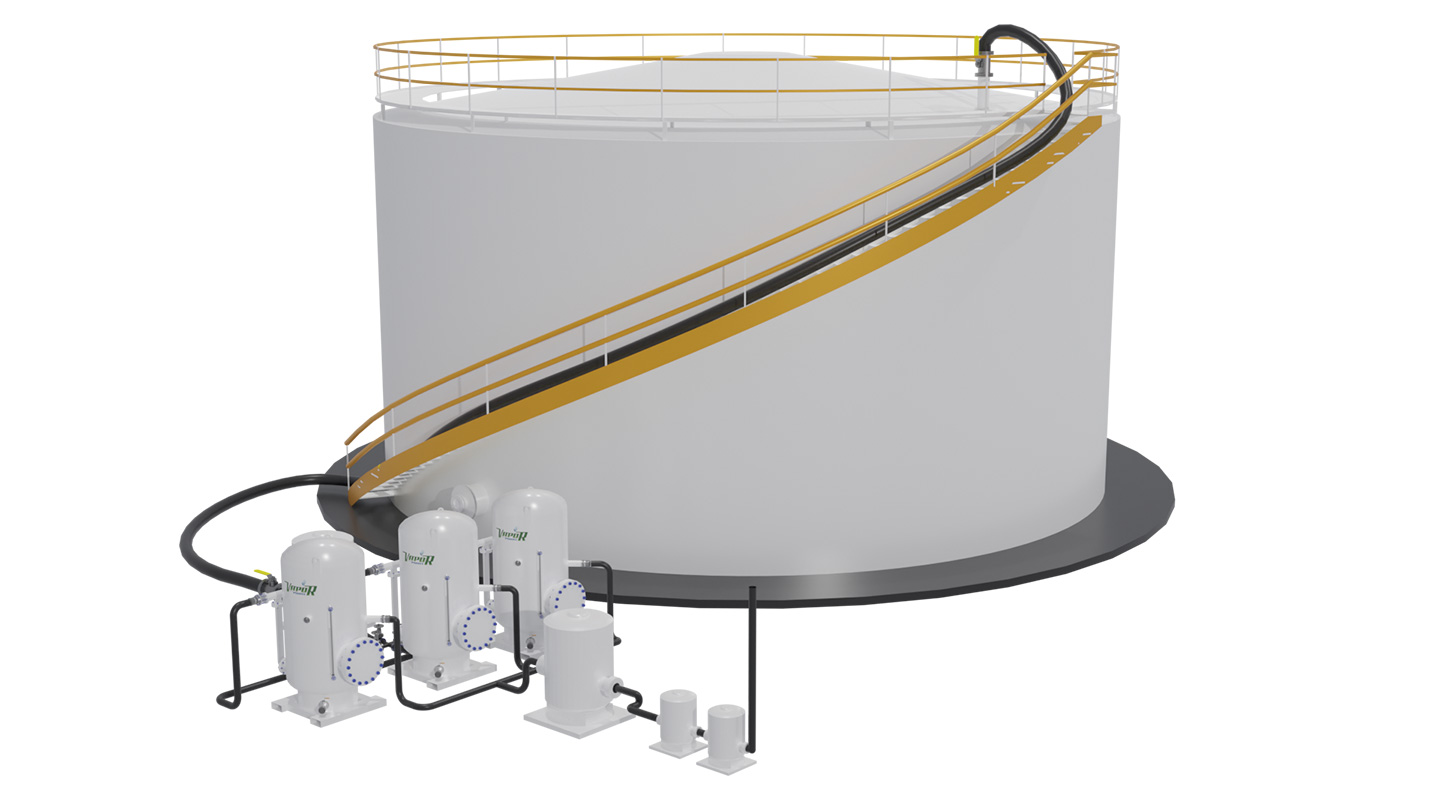

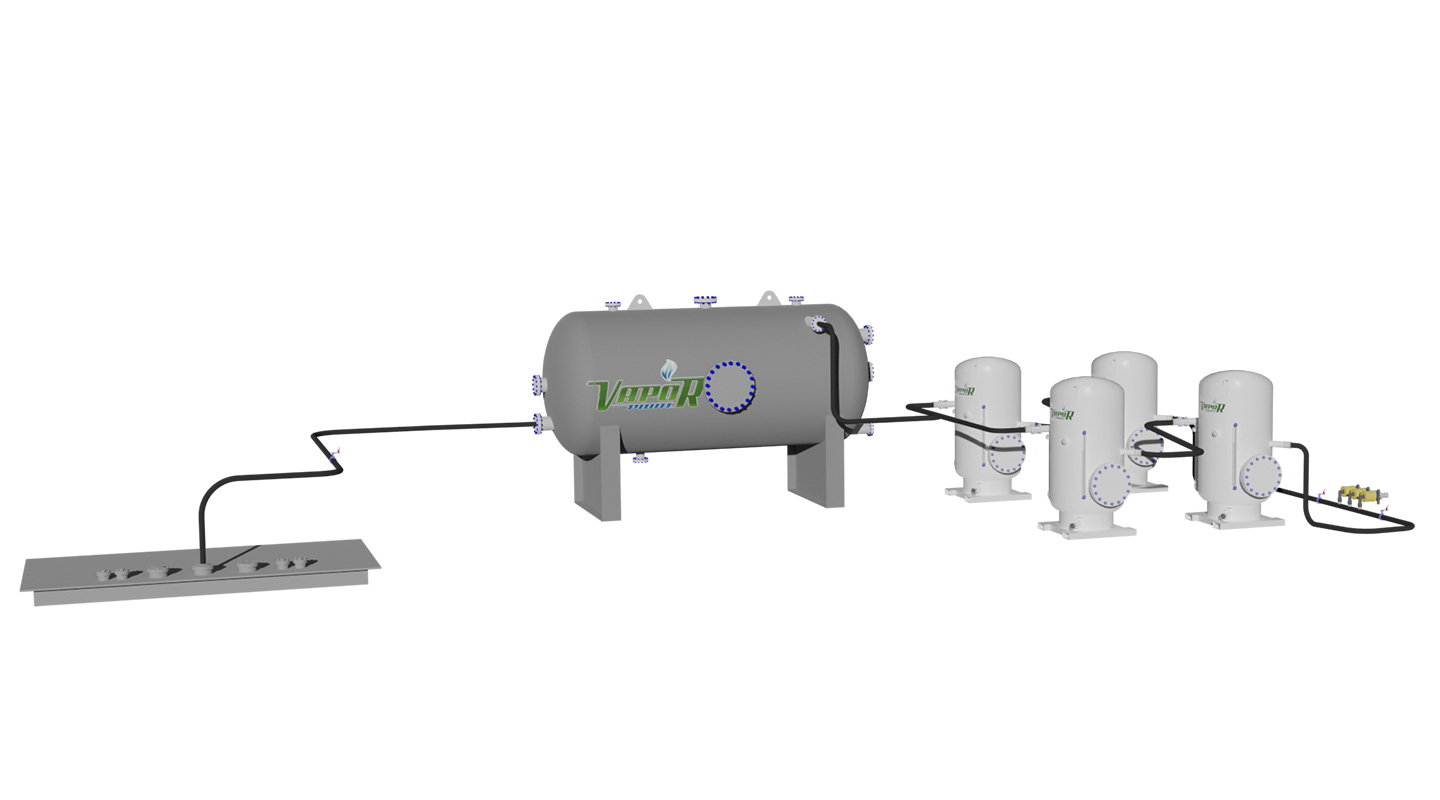

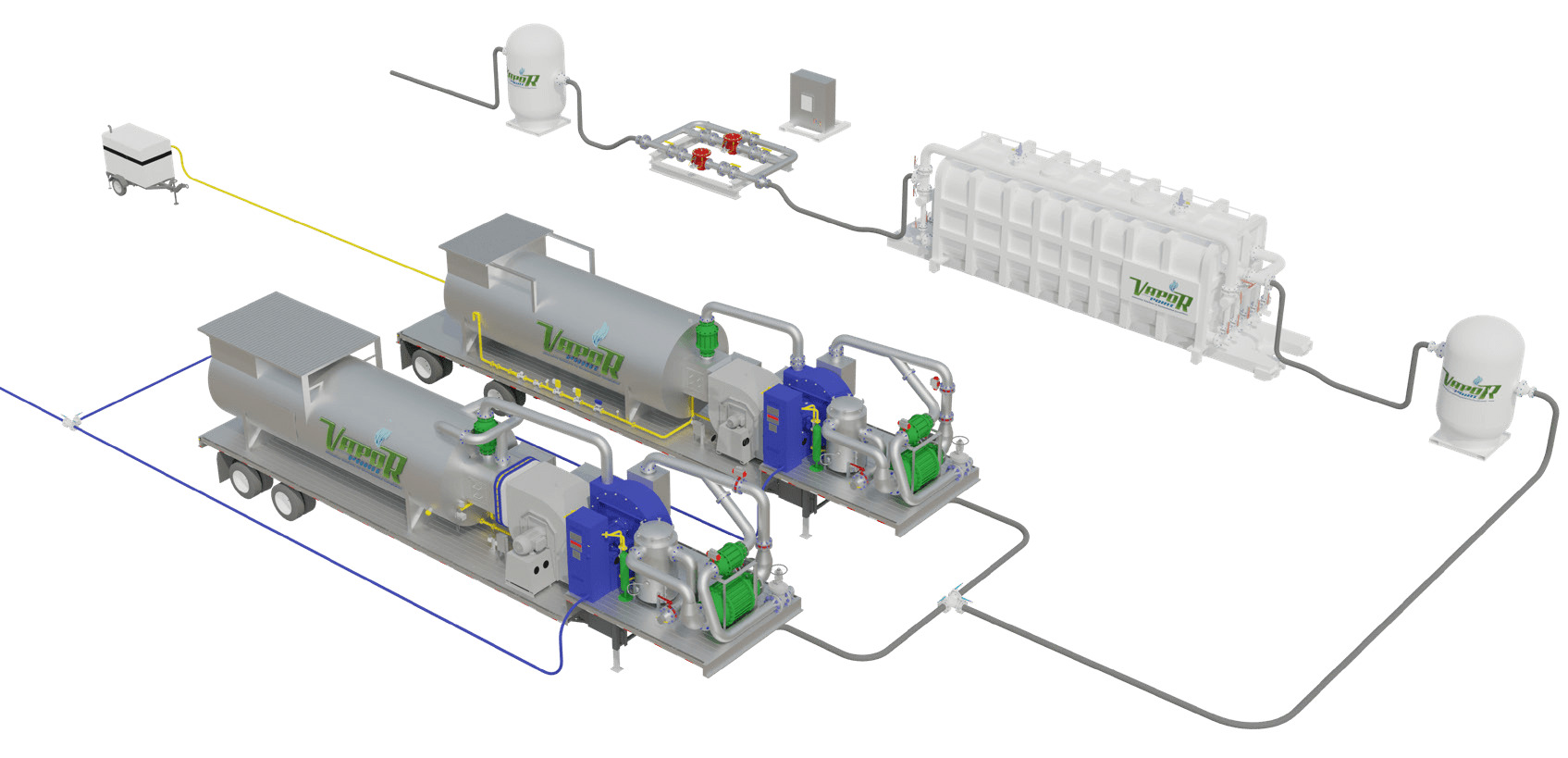

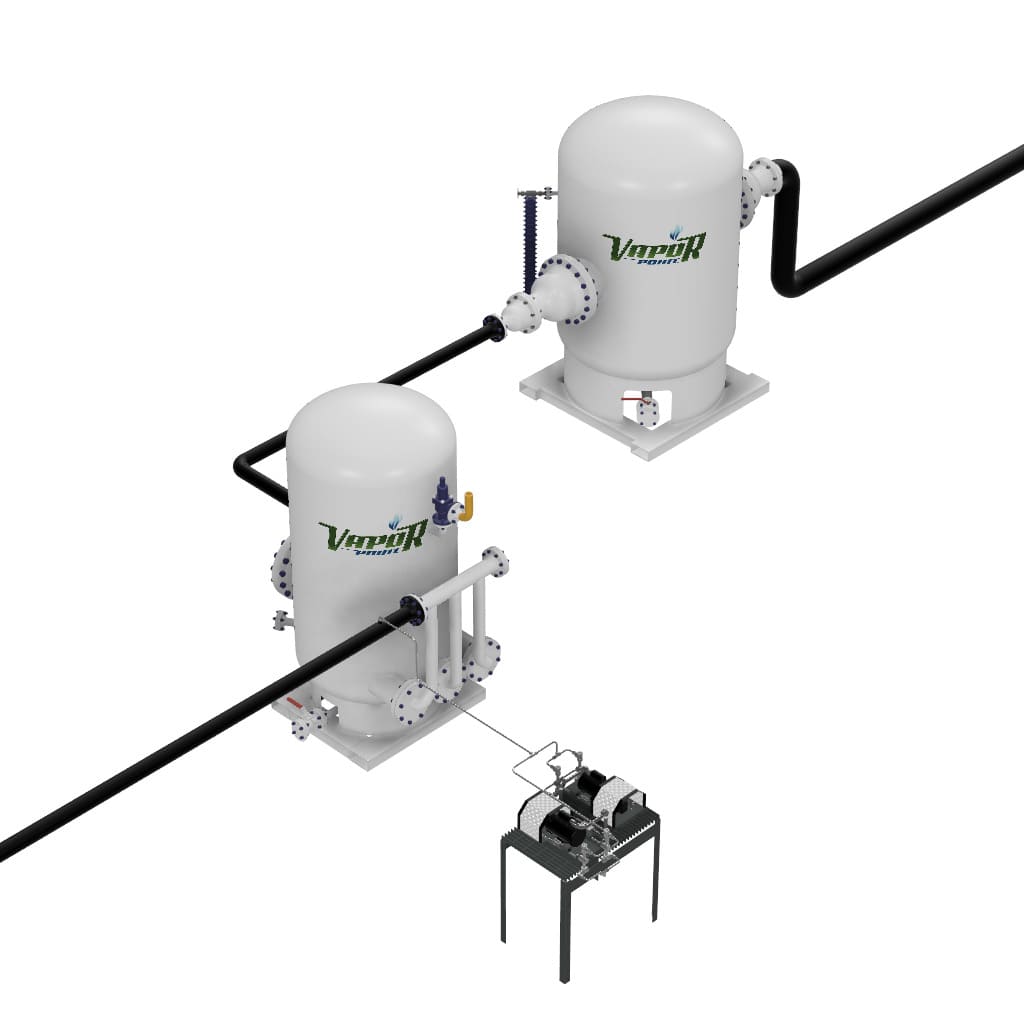

Vapor Point developed On Demand Vapor Control, a pressure sensitive automated system that allows us to modify our standard vacuum venturi controls by eliminating the continuous extraction of vapors.

Read MoreReal-world challenges met with innovative solutions. Our studies showcase Vapor Point’s technical expertise, custom-tailored approaches, and unparalleled commitment to excellence.

Vapor Point developed On Demand Vapor Control, a pressure sensitive automated system that allows us to modify our standard vacuum venturi controls by eliminating the continuous extraction of vapors.

Read More

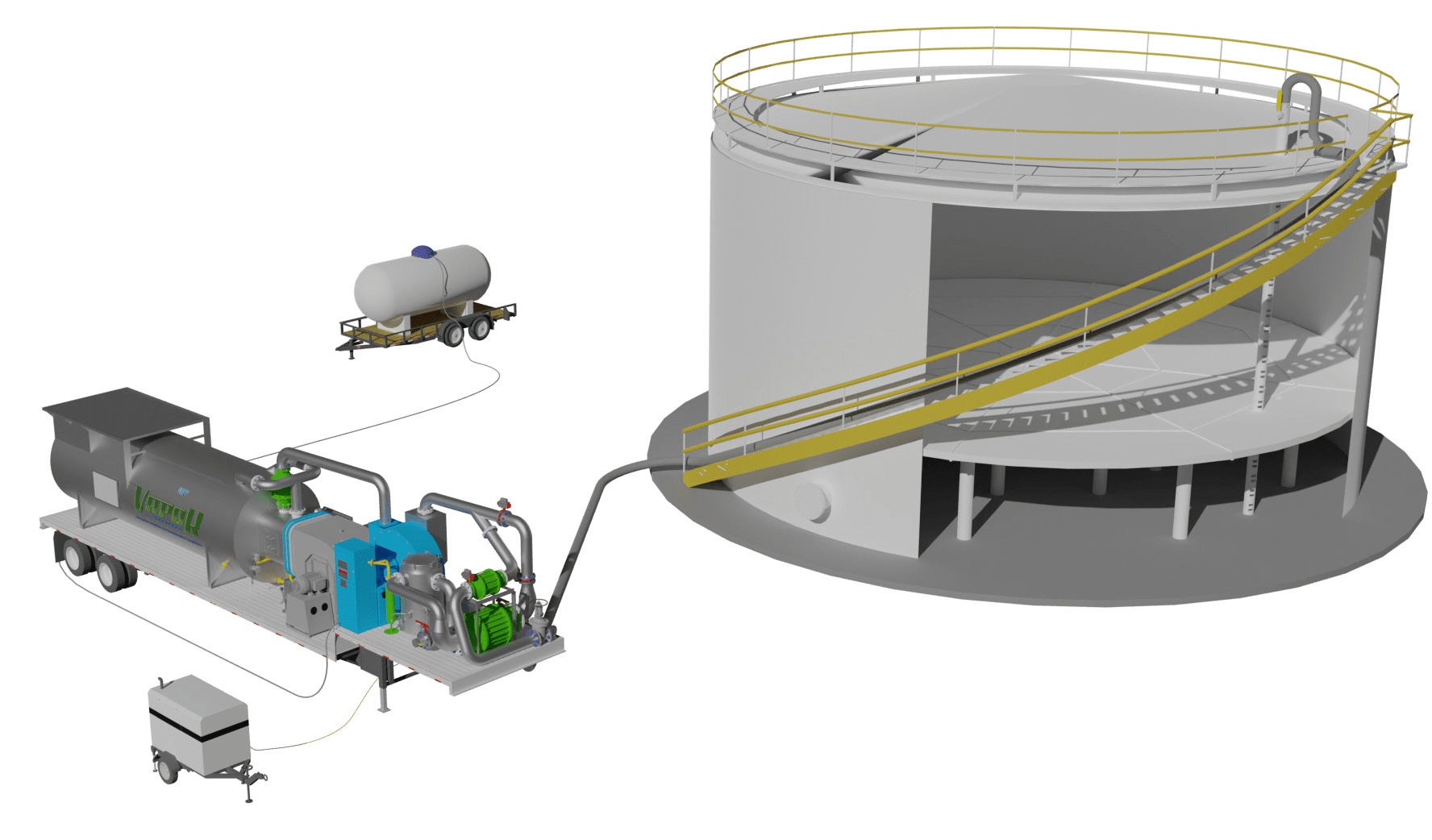

Vapor Point provided the client with our high flow 20 MMBTU thermal combustion unit to reduce the cost and degassing timeframe.

Read More

Gulf coast refinery needs to reduce carbon consumption.

Read More

Hydrotreater unit at a major gulf coast refinery.

Read More

A West Coast Refinery was performing maintenance that required the eductors controlling their sulfur pit to be taken out of service.

Read More

Vapor Point is prepared to help manage both the peak flow and the steady flow by controlling H₂S and VOCs.

Read More

Controlling exhaust emissions from trucks.

Read More

Do you have capacity and temperature issues when flaring?

Read More

A Gulf Coast Refinery wanted to minimize flaring during a 2022 Turnaround.

Read More

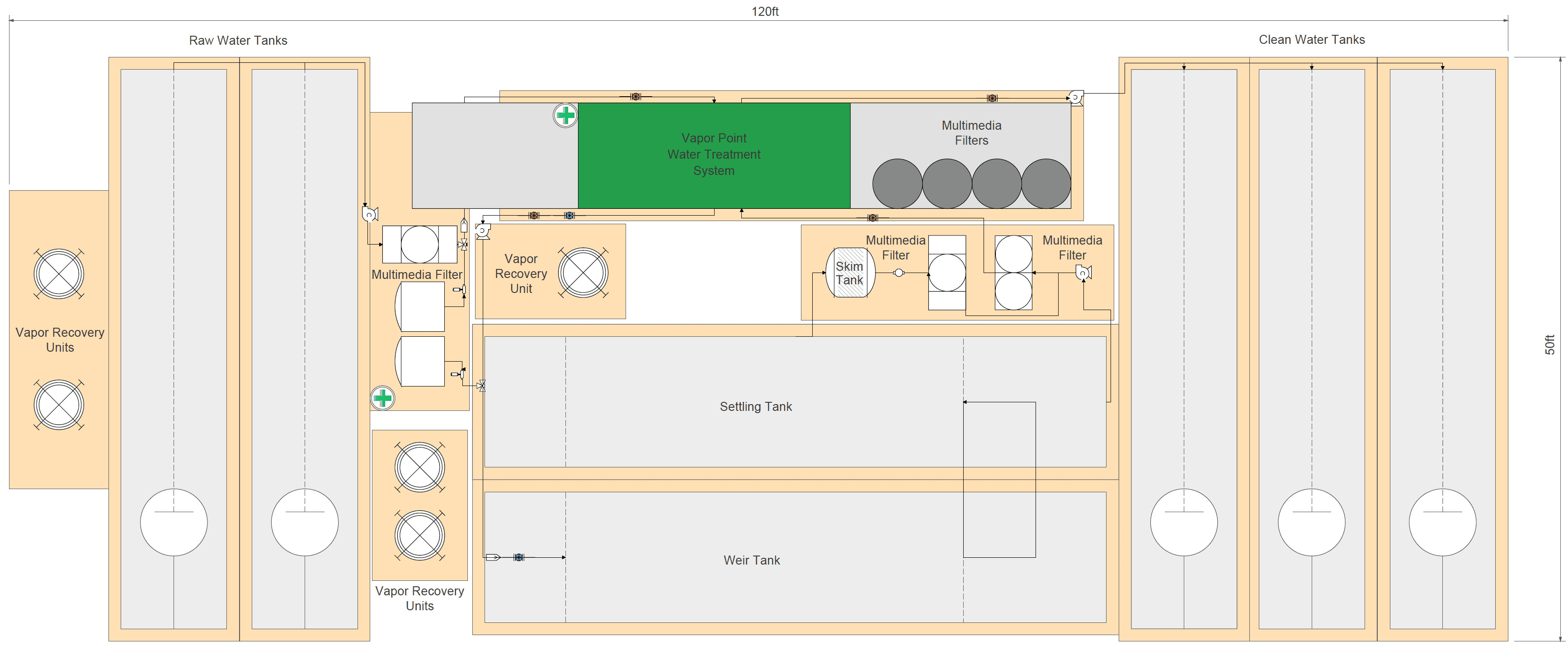

Waste water from multiple cleaning contractors.

Read More

Refiners often face challenges in implementing cost-effective BWON controls while ensuring efficiency.

Read More

Refinery operations often face downtime and unplanned interruptions due to sulfide reduction to flare systems, resulting in additional costs and production loss.

Read More

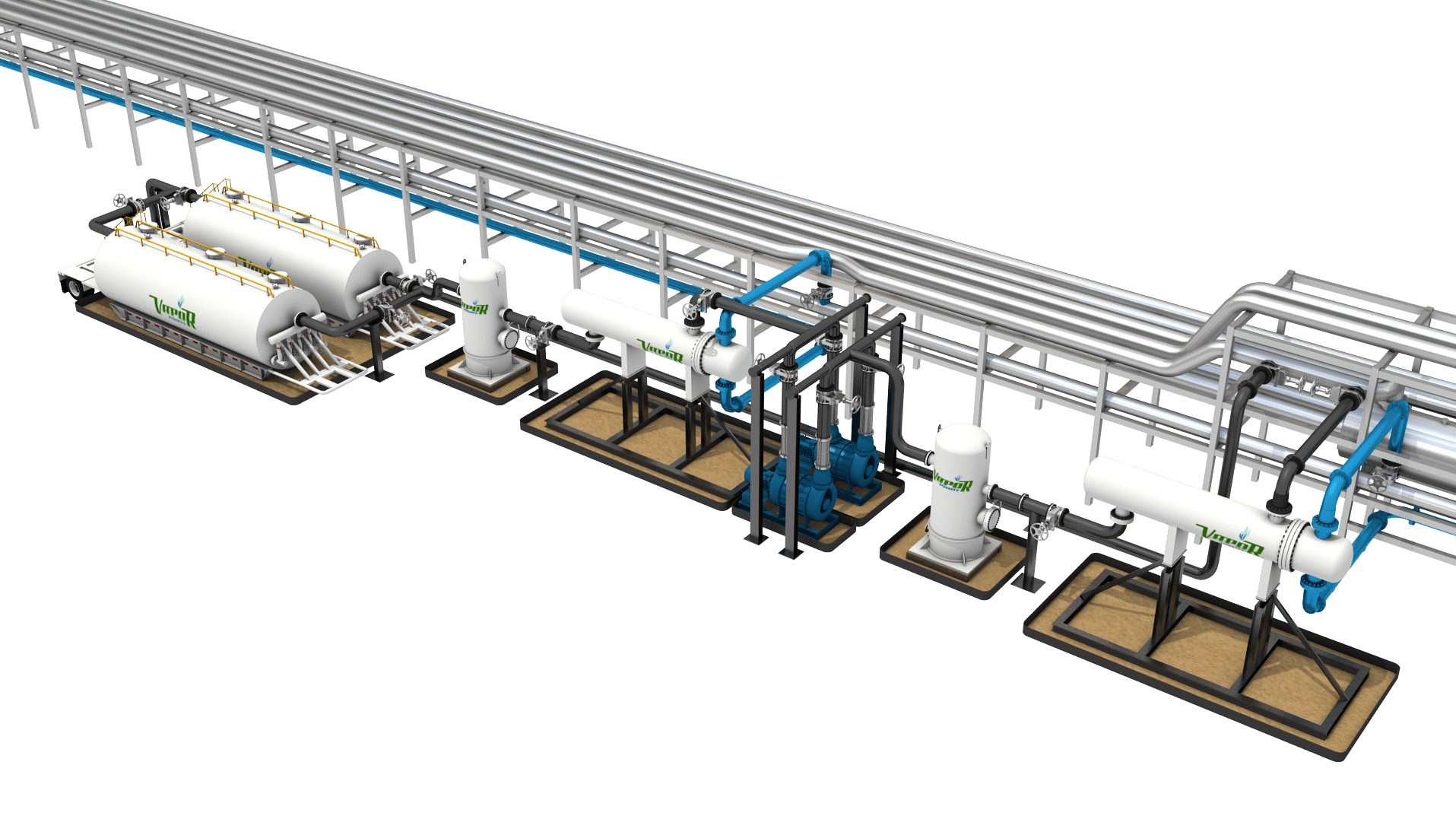

At Vapor Point, we understand the challenges the Oil & Gas industry faces when it comes to controlling hazardous and regulated emissions.

Read More

At Vapor Point, we understand the challenges the Oil & Gas industry faces when it comes to controlling hazardous and regulated emissions.

Read More

A Gulf Coast refinery produces straight run naphtha from their crude unit.

Read More

Dealing with product specification failures can be a daunting task, causing economic hardships for your business.

Read More

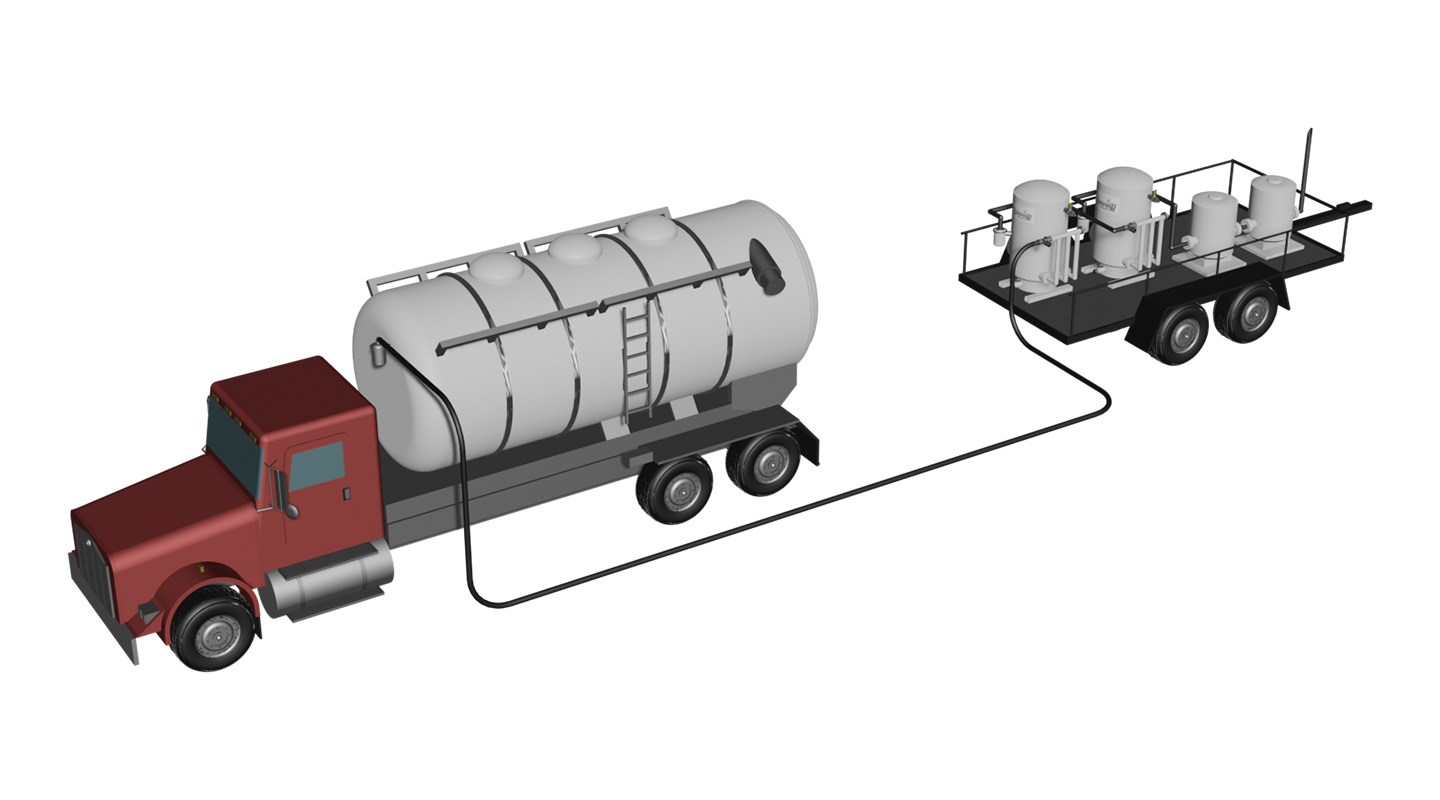

Our client, a prominent producer in the Permian Basin, is focused on extracting crude oil and natural gas.

Read More

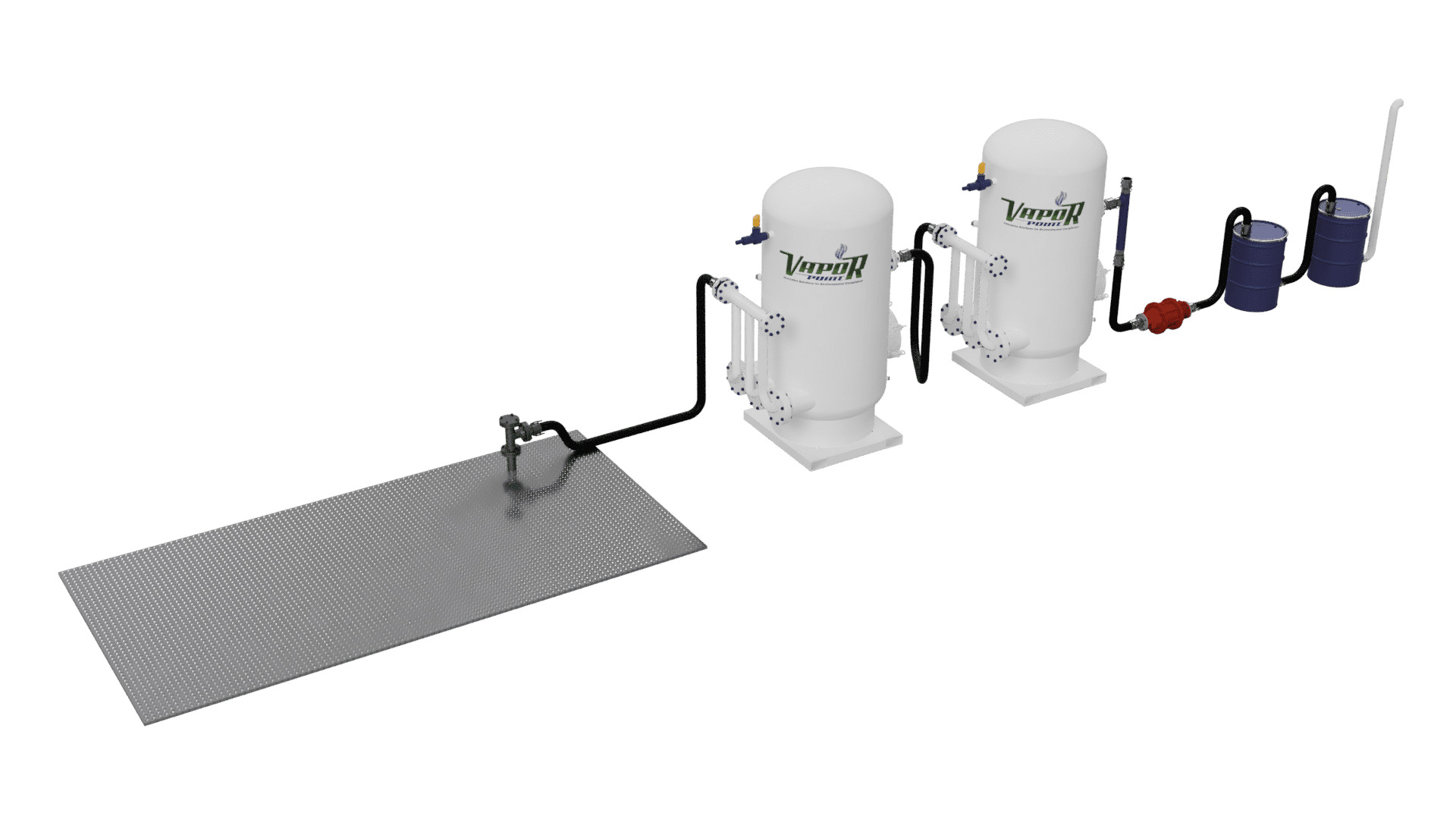

A pipeline customer in Southern California needed to relieve pressure from a crude oil line after a pipeline pigging operation.

Read More

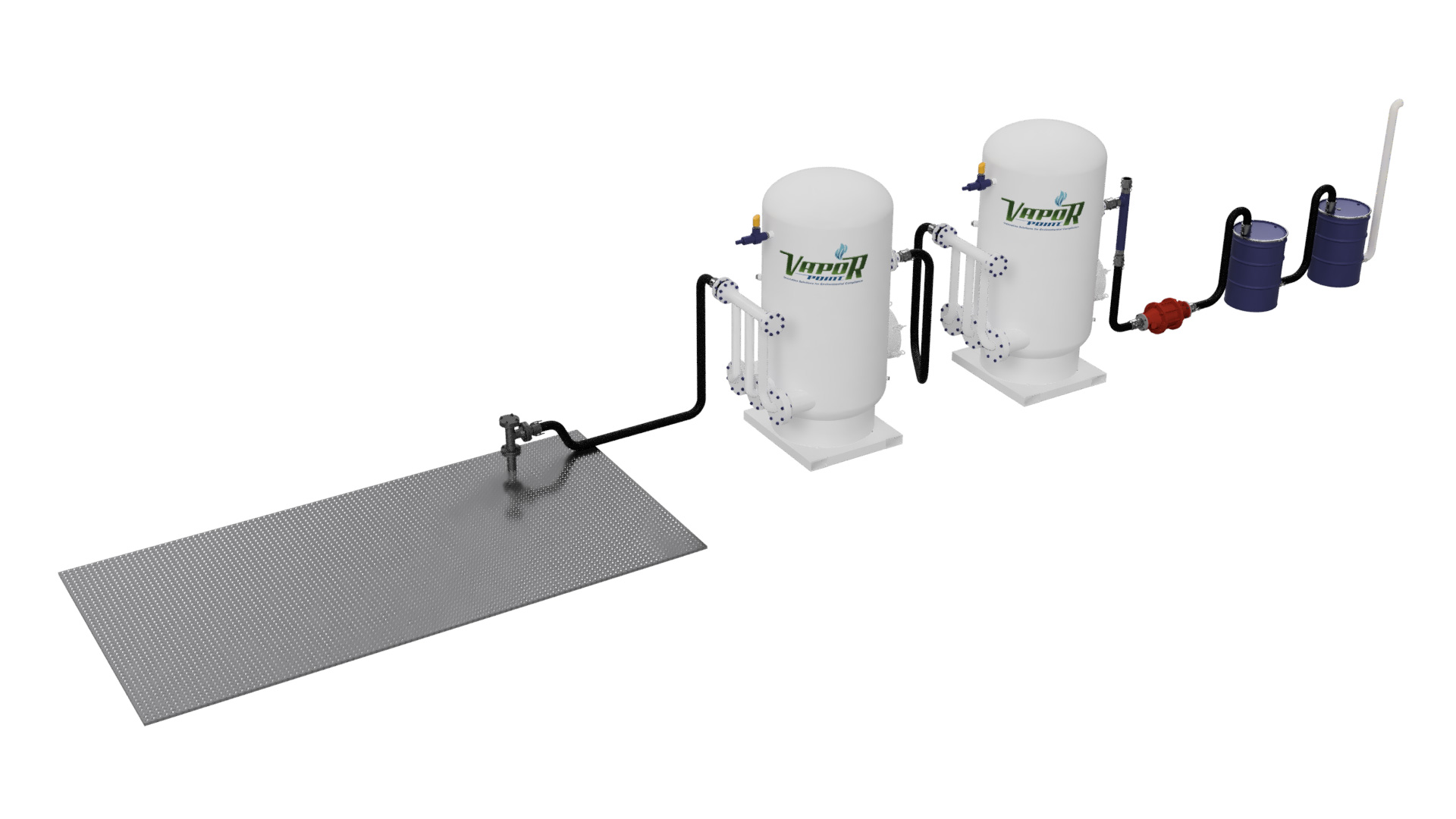

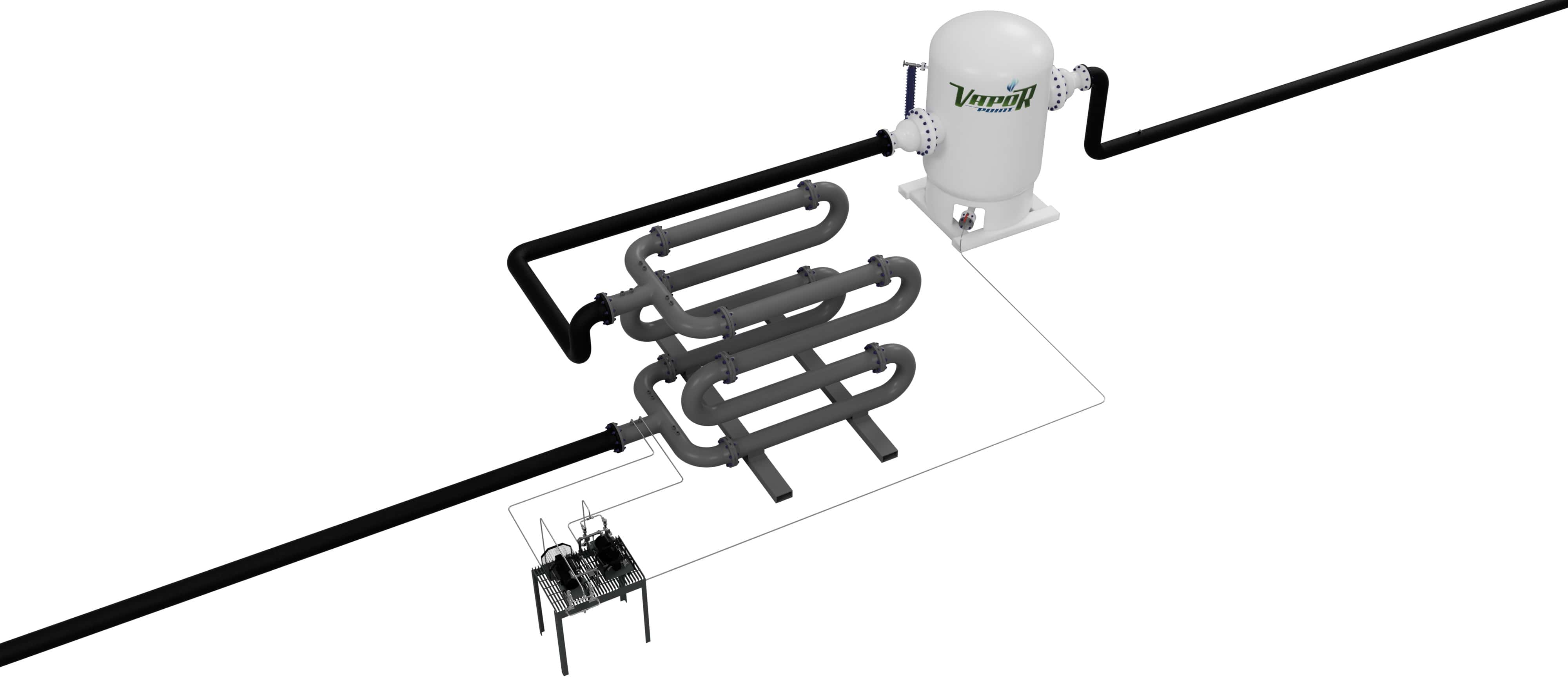

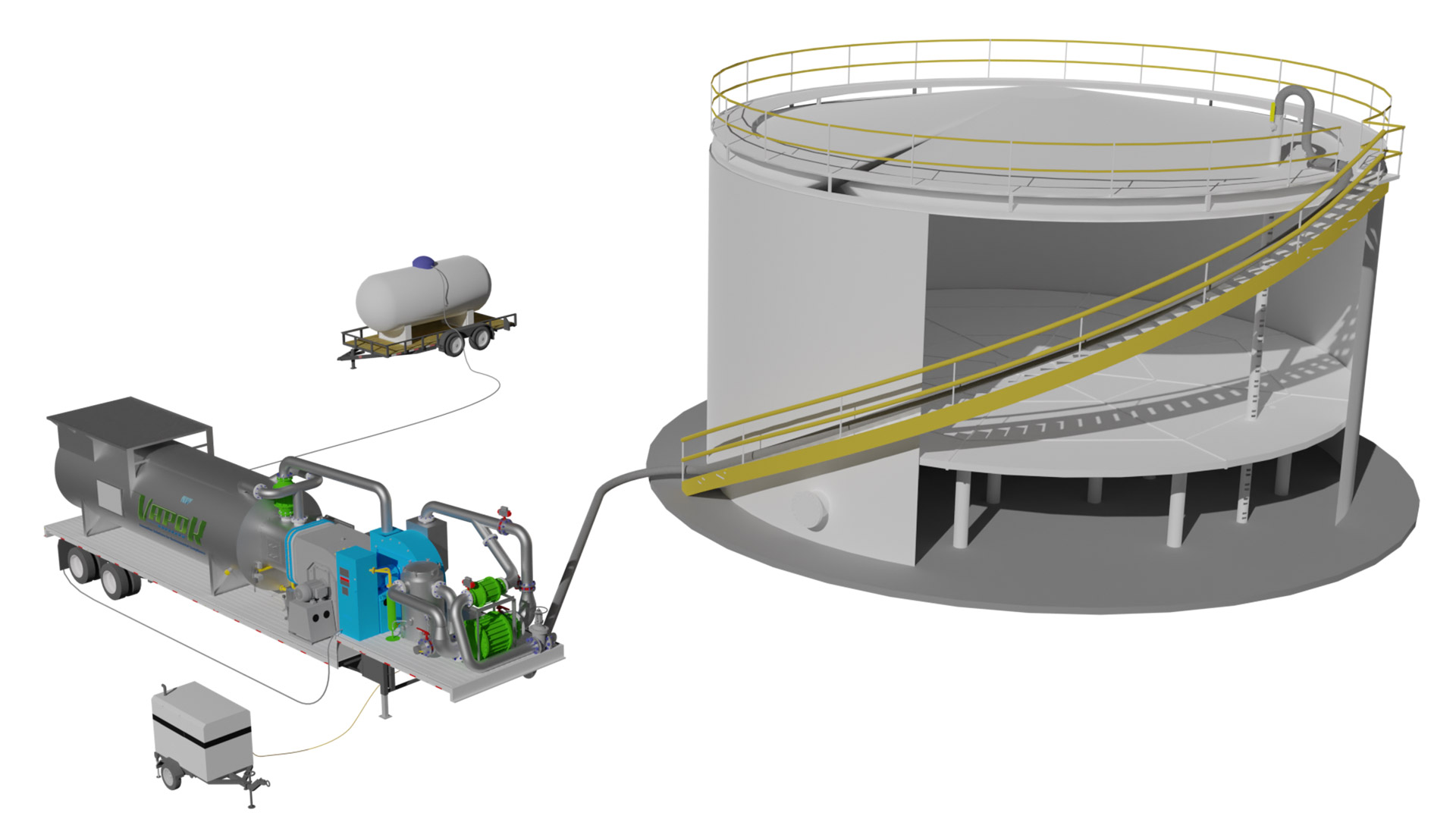

A customer in Houston Ship Channel faced the challenge of refilling a Crude Oil aboveground storage tank at a rate surpassing 10,000 barrels per hour.

Read More

A West Texas refinery faced the challenge of complying with Title V permit conditions during a complex unit turnaround while seeking an alternative to flaring.

Read More

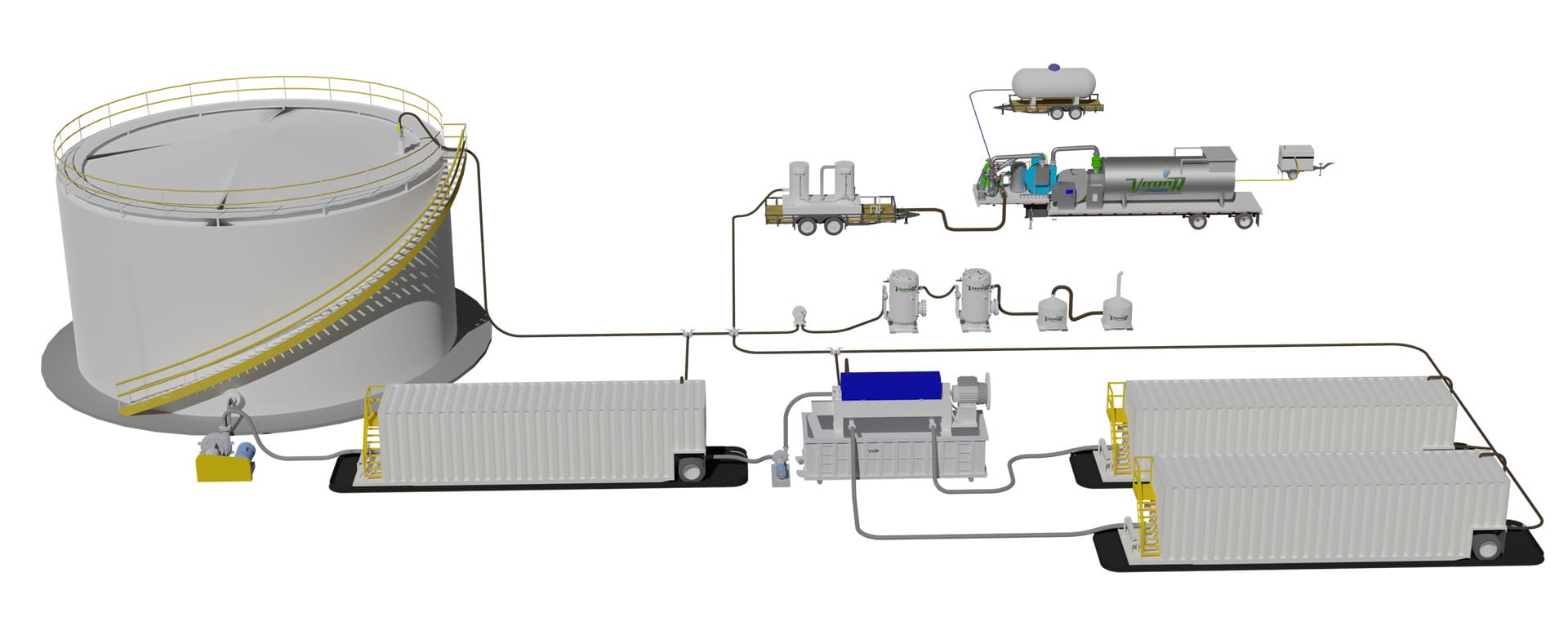

During a routine tank degassing project at a Gulf Coast refinery, an unexpected challenge emerged: the discovery of sludge.

Read More

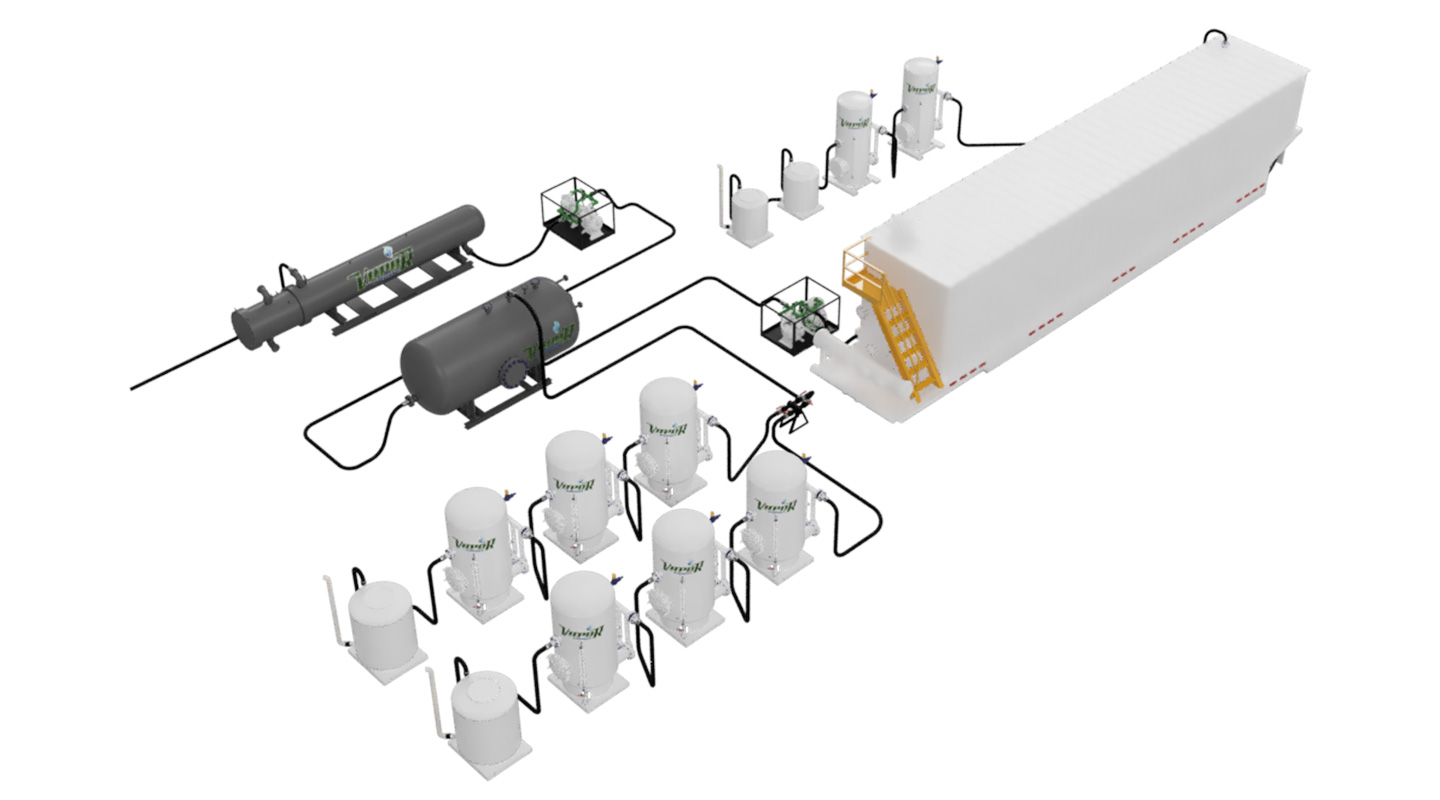

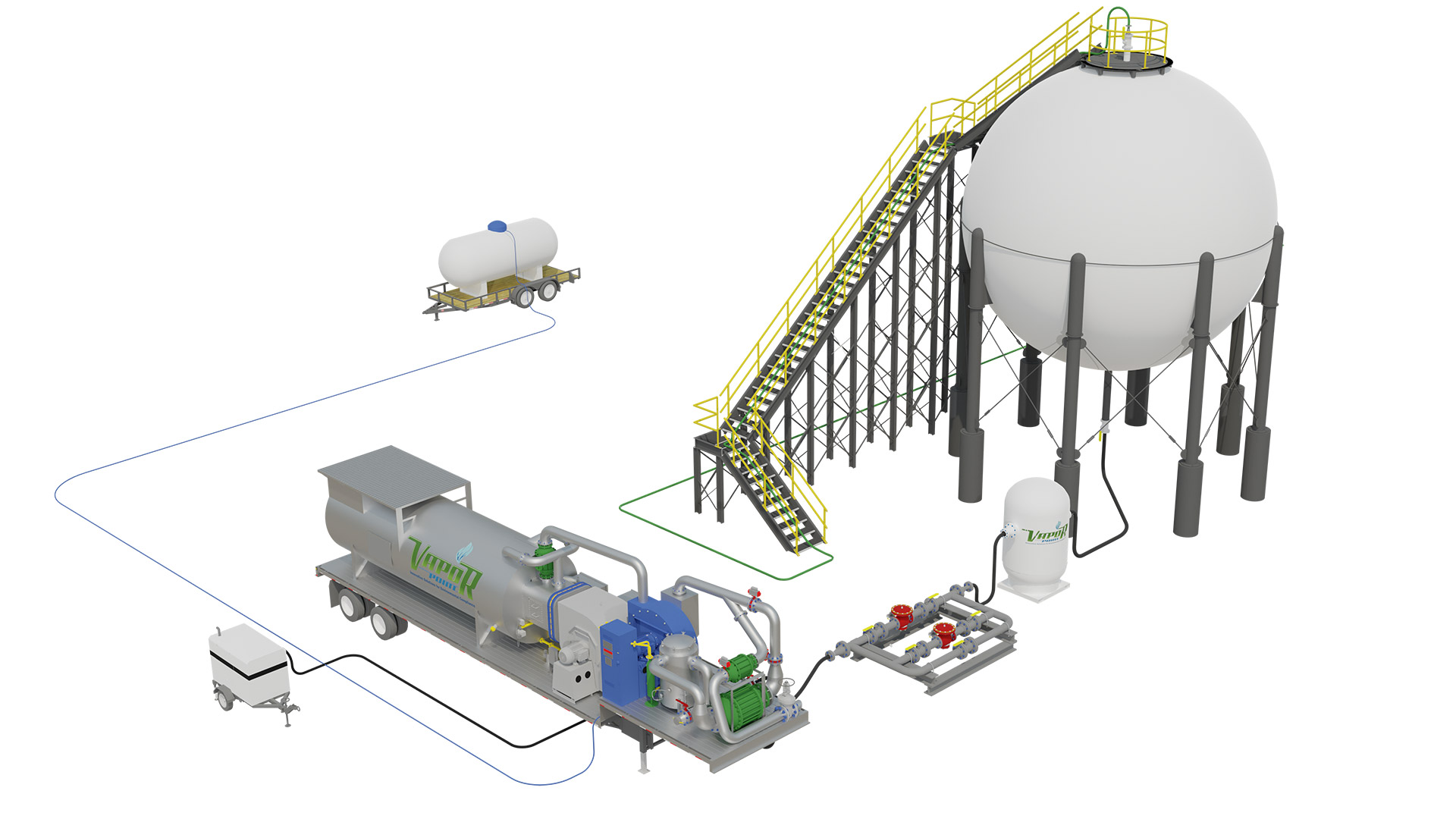

A Gulf Coast refinery faced the task of removing 10-15 large butane and propane spheres from service within six months.

Read More

In order to produce crude oil, the associated produced gas has an inlet hydrogen sulfide concentration near 70,000 ppmv.

Read More