Refiners often face challenges in implementing cost-effective BWON controls while ensuring efficiency. Vapor Point's cutting-edge technology offers a solution to address the significant variability in contaminant concentrations and design vapor control systems for BWON applications.

When the vent gas exhibits consistent flow and concentration, activated carbon or combustion devices are the best design options. Activated carbon, when properly designed and used, proves to be the most effective control device for managing lower concentration hydrocarbon contaminants (less than 1%) and achieving zero emissions. However, when activated carbon encounters high hydrocarbon loading situations, it can become ineffective, failing to remove contaminants from the vent stream and even creating hazardous environments.

System dynamics present considerable challenges for current Best Available Control Technology (BACT). Activated carbon is widely recognized as the most effective technology for BWON applications, while thermal oxidizers/combustors are suitable for highly hydrocarbon-saturated environments. System and vent stream dynamics, including flow rates, temperature, humidity, and contaminant variability, greatly impact the effectiveness of the control system. Traditional control technologies struggle with difficult and dynamic systems, resulting in significant costs for facilities.

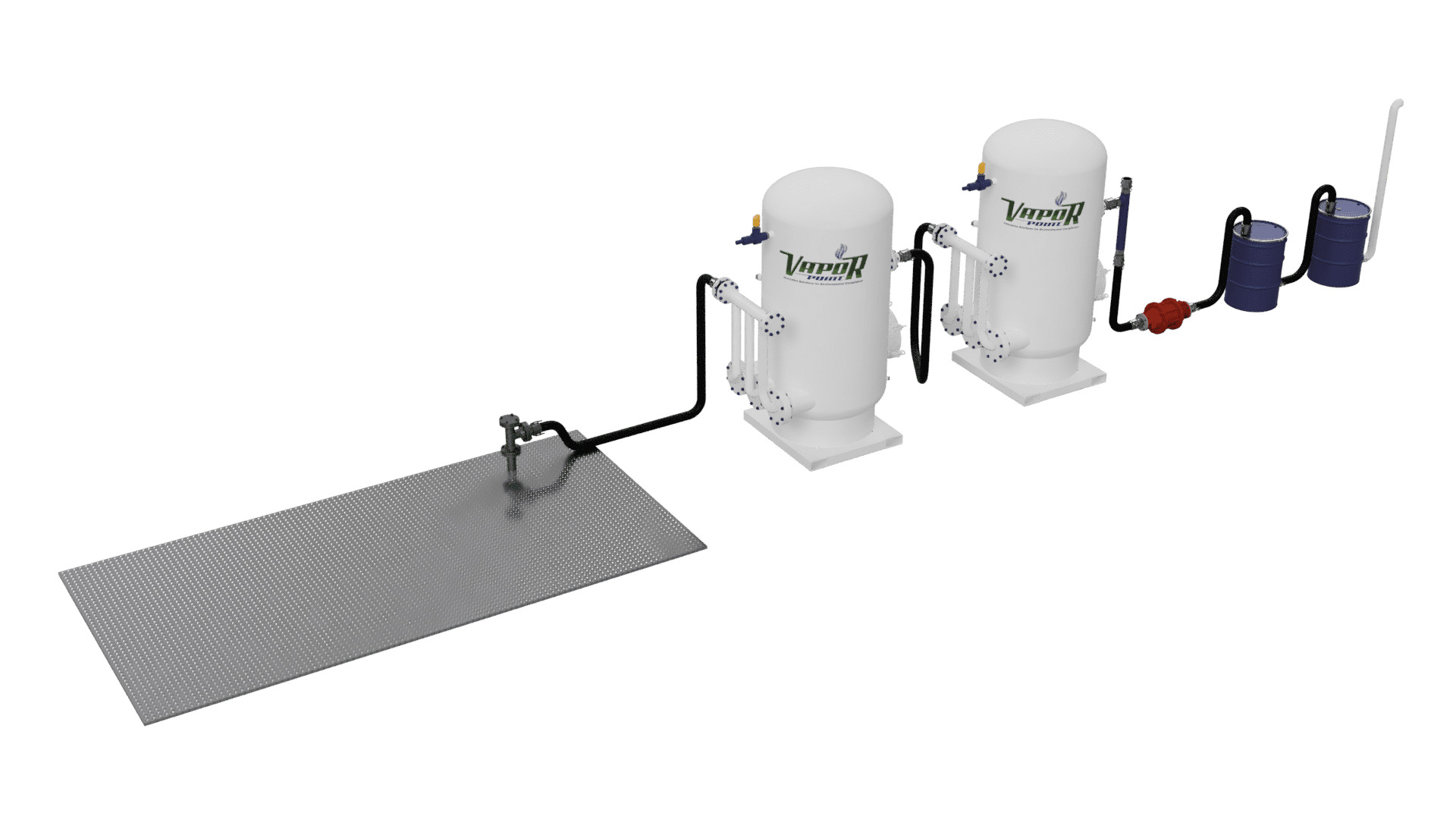

Vapor Point’s VaporLockTM system is designed to handle variability in flow and contaminant concentration, achieving up to 99% recovery or removal of benzene, VOCs, HAPs, and other contaminants. The VaporLockTM system acts as a polishing media, significantly reducing hydrocarbon content in the vapor stream while ensuring consistent flow. This improves carbon utilization, extends canister life, and provides substantial cost savings.

Implementing VaporLockTM control technology reduces hard and soft dollar costs, manages environmental and safety risks, and increases operational efficiencies. Our technology has been successfully applied in API sumps, separators, dissolved air/nitrogen floatation systems, tank vent emissions controls, sludge processing operations, and more. Check out our BWON Emissions Controls white paper to learn how Vapor Point saved one client $2.1MM annually and reduced carbon consumption by 80,000 lbs per month!

Ready to reduce costs and achieve BWON compliance? Contact our sales team to unlock the potential savings and operational efficiencies offered by Vapor Point's innovative technology.