Client’s Challenge

A customer in Houston Ship Channel faced the challenge of refilling a Crude Oil aboveground storage tank at a rate surpassing 10,000 barrels per hour. However, their existing vapor control company lacked thermal units capable of handling such high rates, causing a slowdown in the tank filling process. To address this issue and meet TCEQ permit requirements, Vapor Point provided a higher capacity vapor control unit. This solution ensured optimal control of tank emissions during the refill process.

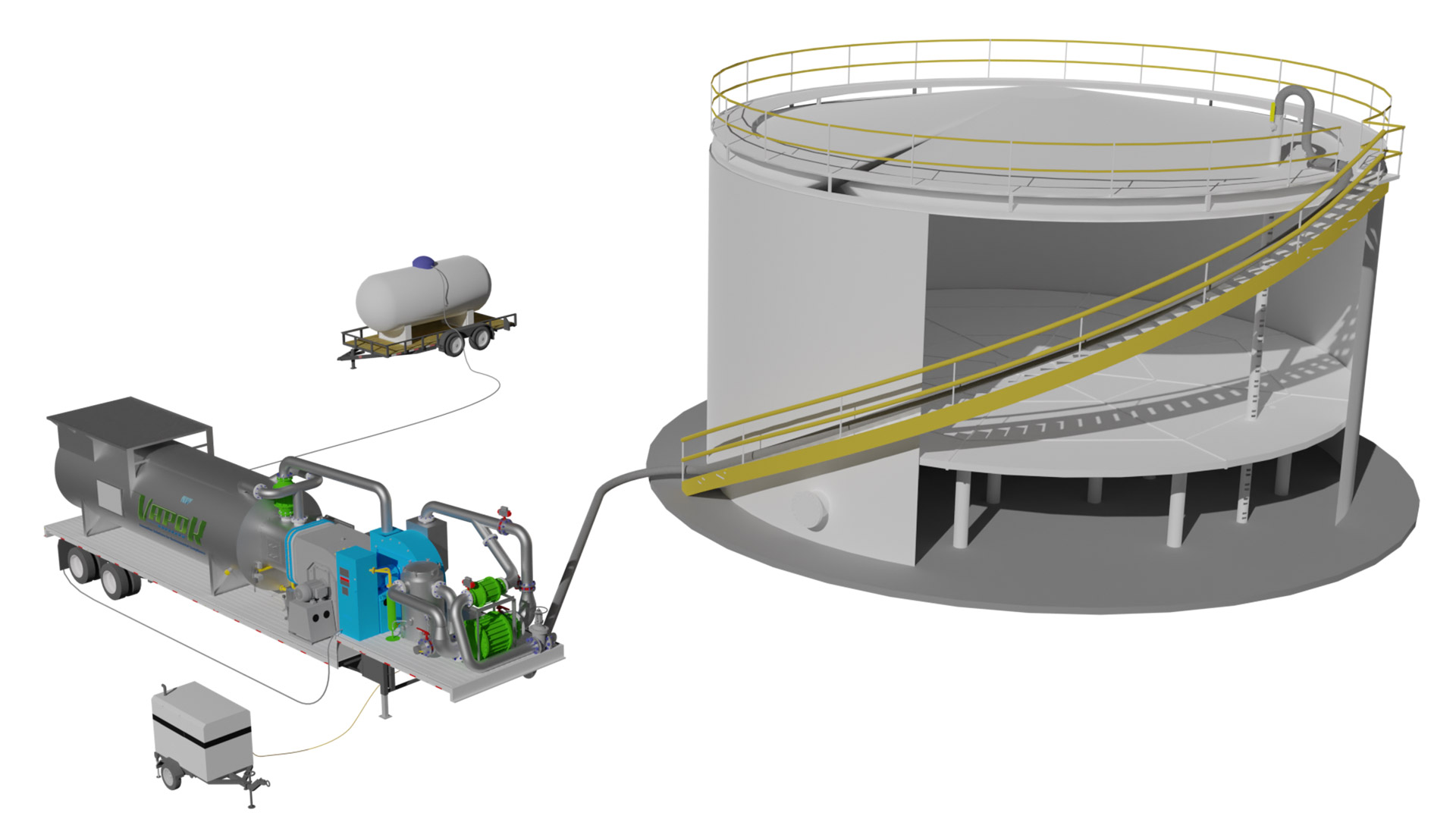

The Vapor Point Solution

Vapor Point stepped in with a higher capacity vapor control unit, ensuring seamless tank filling while complying with TCEQ permit requirements. By providing our 72 MMBTU Vapor Destruction Unit, we enabled the customer to fill their tank at a greater rate than expected, ensuring the project was completed on schedule without any delays. Effective control of tank emissions was achieved using the tank's existing gauge pole and high vapor processing rates, surpassing the tank emission rates during filling.

Vapor Point’s Results

Vapor Point delivered safe and compliant solutions that not only saved the customer from hours of filling delays and potential emissions exceedance, but also resulted in substantial cost savings of thousands of dollars for this specific project. With Vapor Point's expertise and cutting-edge technology, the customer achieved their objectives efficiently and cost-effectively, ensuring a successful and hassle-free outcome.