Client’s Challenge

During a routine tank degassing project at a Gulf Coast refinery, an unexpected challenge emerged: the discovery of sludge. This complication prevented the floating roof from being lowered onto its maintenance legs, a crucial part of the procedure. Upon discovery, the customer requested a centrifuge and related support equipment on-site to begin processing the solids in the tank to a level where the tank could be ready for entry and final tank cleaning.

Vapor Point was enlisted to provide comprehensive vapor control solutions during the solids processing activities. The refinery tank, situated near a fence line, required rigorous odor control to prevent any emissions from the solids processing. Vapor control activities needed to be expertly managed to avoid any delays, including potential volatile organic compounds (VOCs) exposure risks to personnel.

The Vapor Point Solution

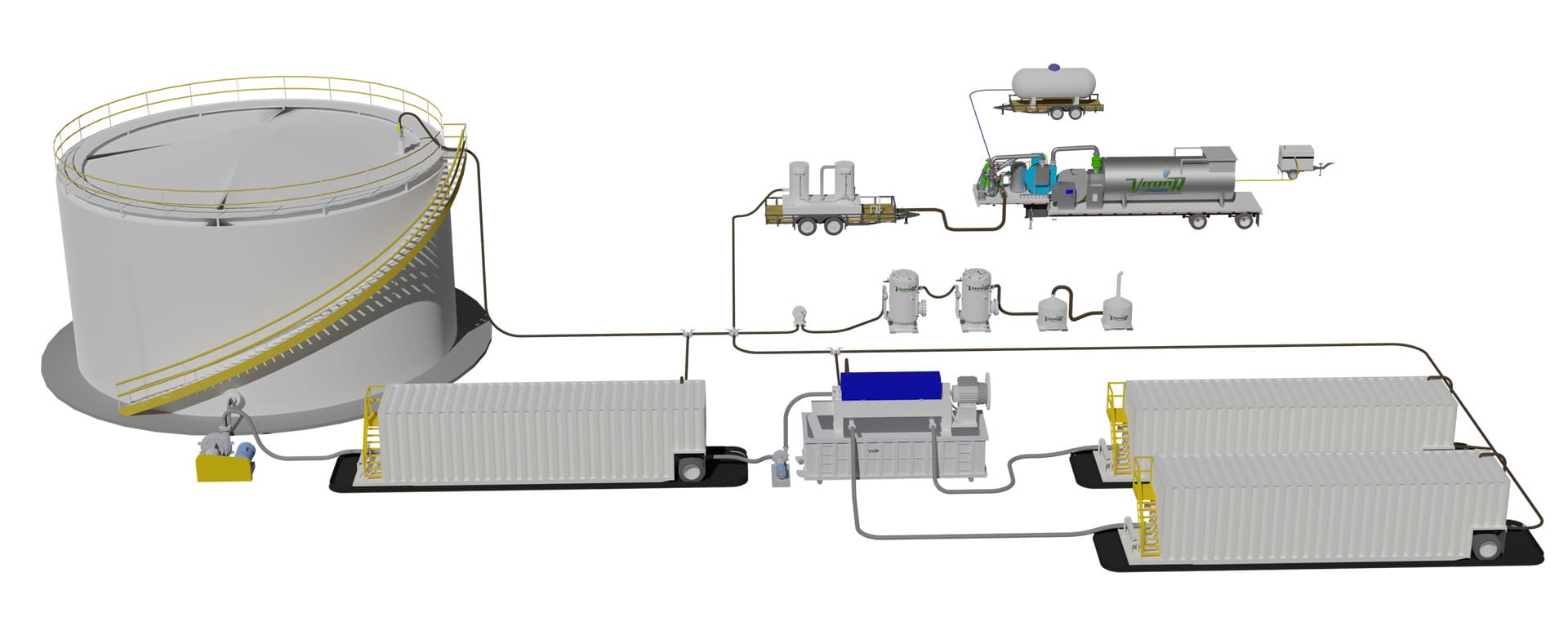

Swiftly responding to the situation, Vapor Point quickly deployed an 8 MMBTU Vapor Combustor and H₂S Scrubber to manage the emissions from the solids processing and the tank. To further ensure optimal results, Vapor Point supplied a backup liquid scrubber and carbon system, ready to address any challenges that could potentially emerge during thermal vapor control.

All vapor sources were connected to a single location to minimize emissions from the processing equipment or tanks. Throughout the project, Vapor Point carried out on-site monitoring of emissions from the processing equipment and also conducted area monitoring. Additionally, Vapor Point conducted rigorous on-site emissions monitoring and area supervision throughout the project, reinforcing our commitment to environmental safety.

Vapor Point’s Results

Successfully completing the solids processing vapor control project, Vapor Point ensured that there were no delays or risks of personnel exposure. Additionally, our precision management resulted in zero exceedances of fence line emission monitoring, facilitating a swift return to service for the customer's tank.

The client expressed high satisfaction with Vapor Point's reliable services. Our robust vapor control strategies ensured that all equipment and the tank remained within the emission limits. Further, we effectively eliminated any risks related to personnel exposure, solidifying our reputation as a trusted provider in industrial vapor control.