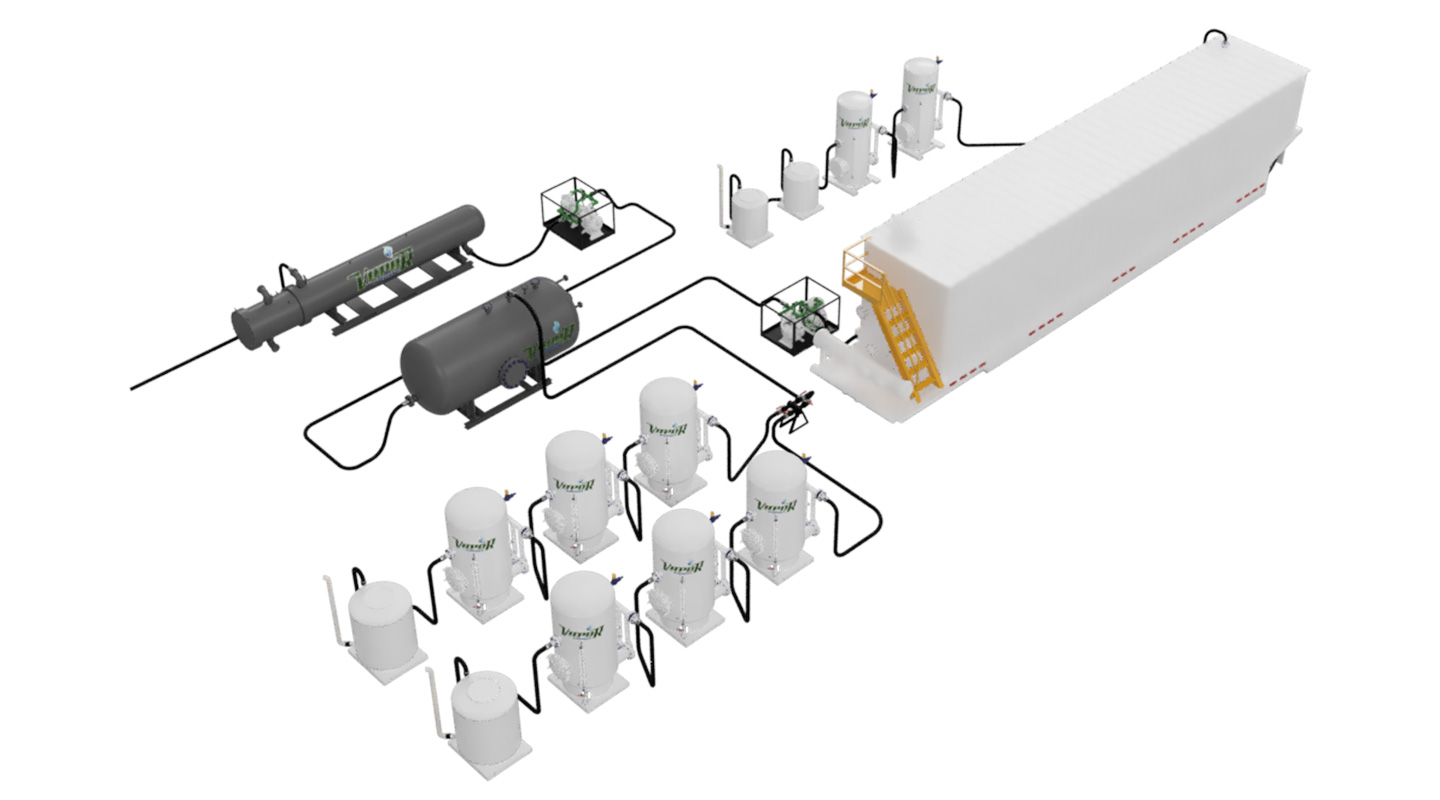

Flareless Chemical Cleaning:

- Predictable alternative to flare during vapor phase unit decontamination

- Evacuation with steam, nitrogen, or liquid pump down to external storage (frac) tanks of liquid and vapor phases

- Vapor phase may be the only purged material

Vapor Point Advantages:

- Allows for complete discharge (vapors) of operating equipment while recovering emissions

- Higher deinventory flow rates and pressures versus limits by conventional storage equipment (frac tanks at 1 PSI max.)

Results:

- Improved unit deinventory performance/ cleaning

- Decreased downtime

Flare Gas Recovery Limited Capacity or Availability During Turnarounds:

- Flare gas loading during turnarounds can reach the capacity of the flare unit and affect continuing process operations

- Fugitive emissions of VOCs, H₂S, Benzene, HAPs, etc.

- Compressor typically temperature limited

- Maintenance ability to isolate “high loading” vapor emission units which can cause upsets to entire facility

- Shutdown schedule optimization

FGR Alternative Turnaround Advantages & Results:

- Allows for point source controls of high emission loading unit blowdowns

- Non-combustion source can be placed close to operating units

- Ability to design larger flow units to accommodate high flowrates / high-loading turnarounds

- Pressure vessel allows for increased purge pressures and flows

- Liquid levels managed by Vapor Point Technicians

- Treating of vapor flows, and reduction in flaring / FGR loading